Corrugated Horns for Microwave and Terahertz operation

TK has, over two decades, built up an unrivaled expertise in the design and manufacture of Corrugated horns - making horns from 2 to 1000 GHz. Our horns are made to a space qualified standard.

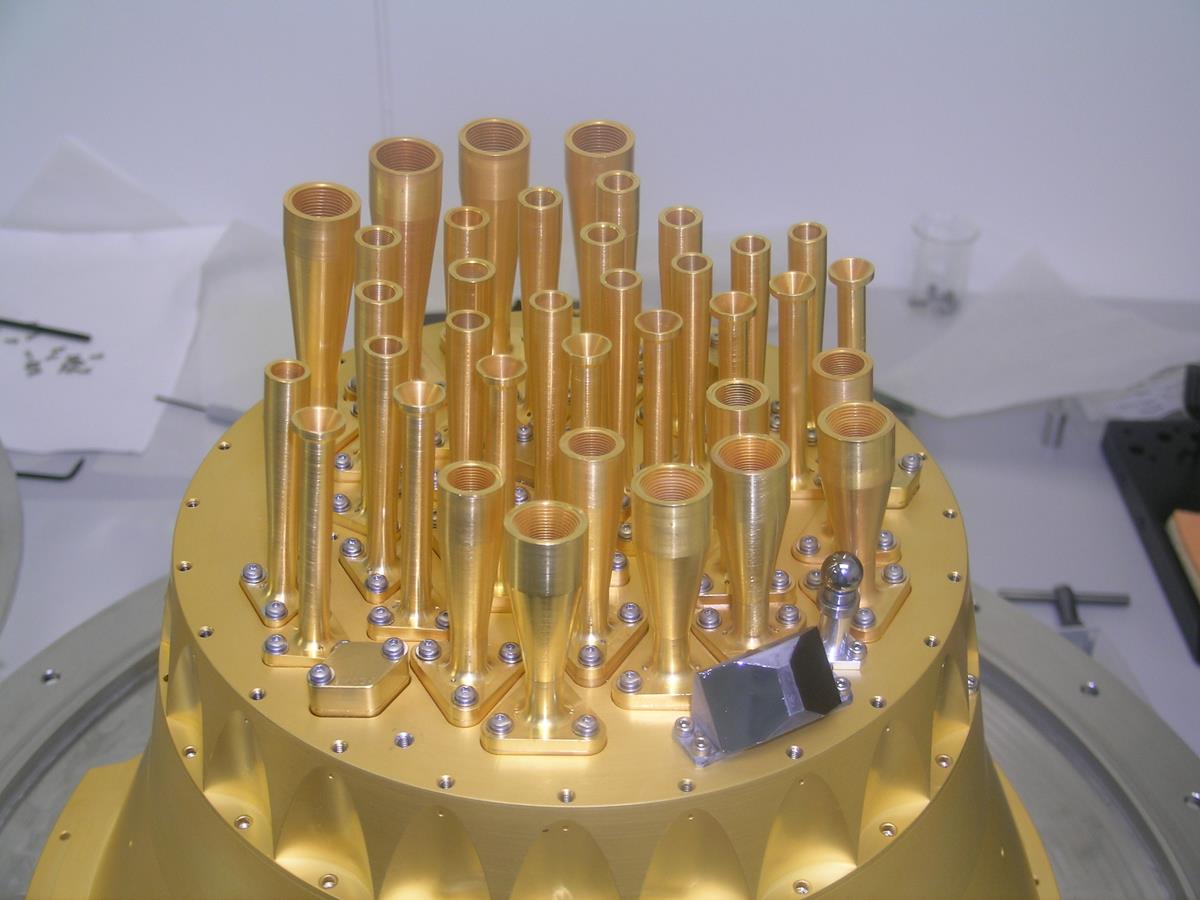

We were co-responsible for the design and manufactured all of the horns for the HFI instrument on Planck - ESA's Cosmic background surveyor: The flight hardware is shown below:

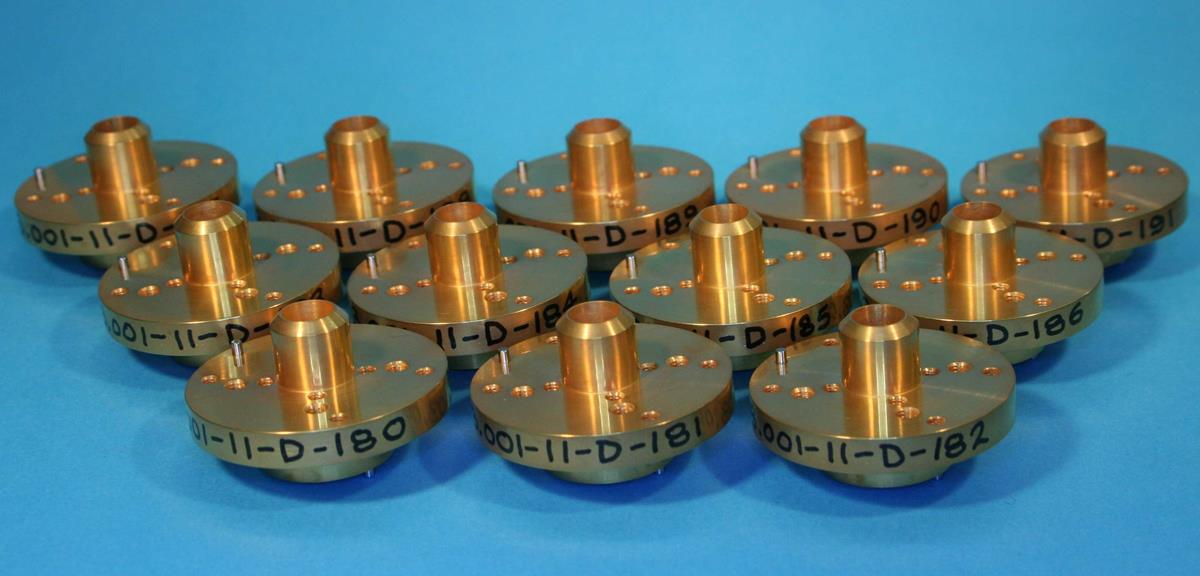

and are responsible for making many of the Band 10 horns in for ALMA operating from 780 to 950 GHz:

Recent (and rather unexpected) advances made by Graham Smith in St Andrews in the design of horns has allowed the production of what we call Ultra Gaussian horns, which can give 99.88% of their power in the fundamental mode.

The photo showns a space-qualified 89 GHz corrugated horn for the AMSU-B microwave radiometer.

Thomas Keating design and manufacturs a large number of corrugated horns from 6 Ghz to 600 GHz and above. They have wide bandwidth, high axial symmetry and low Sidelobes.

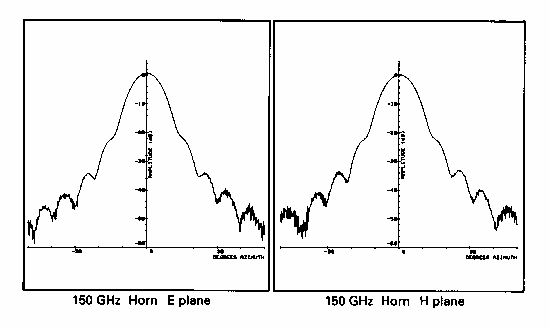

Typical antenna patterns are:

They can be made to operate at cryogenic (Liquid He - 4K) temperatures.

The throat region of one of our horns, showing the Au plating, looks like:

With careful modal analysis - for which we use modal matching software CORRUG - bandwidths of 1 to 1.5 can be achieved.

Here is a plot of Reflection coefficient plotted against frequency for a wideband 70 to 110 GHz horn, showing that for much of the band reflections are below -30dB.

Here are some pictures of our hons uesed in a 3mm Array in NRO, Nobeyama.

The mandrels for our horns are machined on our precision Hardinge CNC lathe And the people who made them:

Eric Baker, Richard Wylde, Trevor Walker and Mick Myers hold a set of corrugated horns for Radioastronomical use at NRO, Nobeyama, Japan.

The photo was taken in the 1990's and we all have slightly less hair now!